- Back

- Tool advisory centre for circular saw blades, band saws for wood cutting

- Saw Blade Alignment on a Table Saw

Saw Blade Alignment on a Table Saw

We advise you to use precise measuring instruments when mounting your saw blade. Mount your saw blade onto the arbor. Adjust the arbor to its maximum height. Verify that the saw blade is parallel to the miter gauge slots. Adjust as needed. This step is necessary to obtain crosscuts with the maximum in quality finish and for setting up the fence for ripping.

The overlap of saw blade teeth over the cutting material must be equal to the height of tungsten tip. The number of teeth cutting simultaneously must be between 2–3.

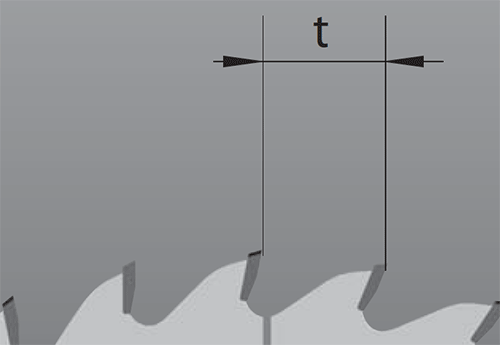

Pict. No. 5 |

Pict. No. 6 |

Here are some useful formulas how to calculate the choice of correct saw blades:

| Legend: t [mm] – tooth pitch h [mm] – thickness of the work piece k [-] – number of teeth in cutting place (2÷3) z [-] – number of teeth of the saw blade D [mm] – sawblade diameter |

These formulas are valid for cross cutting and cutting of laminated materials.

Tab No. 1 shows the maximum RPM of circular saw blade on basis to the diameter of the blade itself. RPM referring to cutting speed 100 m/sec. These are the maximum recommended RPM by the machine builder. When exceeding this limit, the blade will loose its characteristics and danger implied to user may occur.

| Recommended RPM [1/min] | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| D [mm] | Cutting speed vC [m/sec] | ||||||||||

| 10 | 20 | 30 | 40 | 50 | 60 | 70 | 80 | 90 | 100 | ||

| 100 | 1910 | 3820 | 5730 | 7640 | 9550 | 11460 | 13370 | 15280 | 17190 | 19100 | |

| 150 | 1270 | 2550 | 3820 | 5100 | 6370 | 7640 | 8920 | 10190 | 11500 | 12730 | |

| 200 | 960 | 1910 | 2870 | 3820 | 4780 | 5730 | 6690 | 7640 | 8600 | 9550 | |

| 250 | 760 | 1530 | 2290 | 3060 | 3820 | 4590 | 5350 | 6110 | 6880 | 7640 | |

| 300 | 640 | 1270 | 1910 | 2550 | 3180 | 3820 | 4460 | 5100 | 5740 | 6370 | |

| 350 | 550 | 1090 | 1640 | 2180 | 2730 | 3280 | 3820 | 4370 | 4900 | 5460 | |

| 400 | 480 | 960 | 1430 | 1910 | 2390 | 2870 | 3340 | 3820 | 4300 | 4780 | |

| 450 | 430 | 850 | 1270 | 1700 | 2120 | 2550 | 2970 | 3400 | 3820 | 4250 | |

| 500 | 380 | 760 | 1150 | 1530 | 1910 | 2290 | 2680 | 3060 | 3440 | 3820 | |

| 550 | 350 | 690 | 1040 | 1390 | 1740 | 2080 | 2430 | 2780 | 3120 | 3470 | |

| 600 | 320 | 640 | 960 | 1270 | 1590 | 1910 | 2230 | 2550 | 2880 | 3180 | |

| 650 | 290 | 590 | 880 | 1180 | 1470 | 1760 | 2060 | 2350 | 2640 | 2940 | |

| 700 | 270 | 550 | 820 | 1090 | 1360 | 1640 | 1910 | 2180 | 2450 | 2730 | |

| 750 | 250 | 510 | 760 | 1020 | 1270 | 1530 | 1780 | 2040 | 2290 | 2550 | |

| 800 | 240 | 480 | 720 | 950 | 1190 | 1430 | 1670 | 1910 | 2150 | 2390 | |

Legend:

vc [m/s] – cutting speed

D [mm] – diameter of saw blade

n [1/min] – recommended RPM

s [m/min] – feed speed

z [-] – number of teeth

sz [mm/zub] – feed speed/tooth

| Recommended values of feed/tooth | ||

|---|---|---|

| Material | Feed speed sZ [mm/tooth] | |

| Soft woods | Cutting along the grain | 0,2 - 0,3 |

| Cutting across the grain | 0,1 - 0,2 | |

| Hard woods | 0,06 - 0,15 | |

| Chipboard | 0,1 - 0,25 | |

| Plywood | 0,05 - 0,12 | |

| Laminated boards | 0,05 - 0,1 | |

| Non-ferrous metals and plastics | 0,02 - 0,05 | |

Tool advisory centre for circular saw blades, band saws for wood cutting

Have you not found the most suitable tool for your application?

Please, contact us, we will make them for you.